About Us

A.P. Precision Auto Pvt.Ltd, are A Reputed Name For Manufacturing Of Press Tools, Dies and Plastic Moulds, Jigs, Fixtures, Receiving Gauges, Drilling Jigs / Fixtures, VMC Milling Fixtures, Special Purpose Machines (SPM), Roboting Welding Fixtures, Assy./ Sub Assy., Pipe Bending Machine Dies, On Line Fixtures, Reliability And Performance, Castor/Trolly Wheels.

Since 2000-2001 A.P. Precision Auto Pvt.Ltd had started to manufactured first tooling. Then we had continually manufactured the different type of tooling during the 10 years period, under the able leadership of Mr. Suresh Chand (Managing Director) & Mr. Ashok Kumar. (Technical Director), a qualified engineer having good knowledge and specialization of tooling and sheet metal components.

Today A.P. Precision Auto Pvt.Ltd, regarded as one of the leading manufacturers, supplier of sheet metal components including tools, dies, jigs, fixtures and more. These find application in varied engineering industries.

We have setup a well equipped standard room to control The quality of all the tooling and all precision products are inspected in the standard room with temp. Controlled at 20~22 degrees

Products

We are expert in providing a quality range of precision Dies, jigs and Fixtures. Materials we use in manufacturing these products are procured from reliable vendors. Our excellent team and infrastructure unit help us in delivering products of International standards that meet the requirements of a number of industries. Our array of products include: Welding Jigs and Fixtures, MSW – Multi Spot Welding Machines, SPM – Special Purpose Machines, Welding Accessories, MIG Welding Accessories, Spot Welding Accessories, Welding Equipment, Robotics, Press Tools and Receiving Gauges and Panel Checkers.

Infrastructure

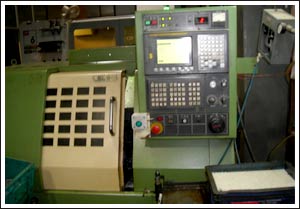

Quality is delivered only when you have a sound infrastructure. We have a state-of-art Infrastructure that is self sufficient for our products range. We have a well developed and completely equipped manufacturing unit spread in a huge area. With the use of latest manufacturing facilities, we are capable enough to design and fabricate products of International standard, which have high functional attributes and require least maintenance.

Machine Installed

(A) CNC:

- Turning Centeres – 04 Nos. 10

- Verticle/ Horizontal Boring M/C – 01 No. 03

- Milling M/Cs With Dro – 05 Nos. 07

- Veticle Machining Centers – 02 No. 03

(B) AUTOMATIC/ SEMI AUTOMATIC

- Lathes : 05 Nos.

- Surface Grinders – 04 Nos.

- Verticle Drill M/C – 03 Nos.

- Power Hacksaws : 02 Nos. 03

(C) WELDING:

- Tig Welding

- Mig/Mag Welding

- Arc Welding

(D) UTILITIES:

- DG Set 63 KVA : 02 Nos

- Air Compressor 75 CFM : 02 Nos

Quality

Quality is an extremely important aspect in our entire work process. We stick to the inflexible quality standards when it comes to manufacturing of products. We assure a premium range of products like welding accessory, MIG welding accessories, Mig welding equipment, welding tables, welding screen, Mig welding machines that successfully meet the technical specifications of ISO 9001:2008 standards. We follow a strict quality control policy which assist us to provide Zero-defect range.

Our Clients

Owing to the high quality of products and standards we maintain, we have been able to serve a large list of clients. Their believe in us can be understood from the fact that we have been regularly receiving a number of orders from same clients. Some of our esteemed clients are listed below:

| 1. | Maruti Udyog Limited | Gurgaon |

| 2. | Hero Honda Motors Ltd. | Dharuhera |

| 3. | Caparo Maruti Limited | Gurgaon |

| 4. | Caparo Engineering India Pvt. Ltd. | Noida |

| 5. | Caparo Maruti Ltd. | Bawal |

| 6. | Capara Engineering India Pvt. Ltd. | Chennai |

| 7. | Caparo Engineering India Pvt. Ltd. | Halol |

| 8. | SKH Metals Ltd. | Gurgaon |

| 9. | Hella Electronics Pvt. Ltd. | Gurgaon |

| 10. | Rasandik Engg Industries Ltd. | Sohna |

| 11. | Max-Op Engineering Co. Pvt. Ltd. | Gurgaon |

| 12. | Suneel Auto Component Pvt. Ltd. | Gurgaon |

| 13. | Vee Gee Industries | Faridabad |

| 14. | Daikin Airconditioning India Pvt. Ltd. | Gurgaon |

| 15. | Urastun Metal Industries Pvt. Ltd. | Faridabad |

| 16. | Thai Summit Neel Auto Pvt. Ltd. | Gurgaon |

| 17. | Horizon Industrial Products Pvt. Ltd. | New Delhi |

| 18. | Maruti Suzuki India Ltd. | IMT Manesar |

| 19. | STI Sanoh India Ltd. | Gurgaon |

| 20. | VE Commercial Vehicles Ltd. (Eicher) | Dhar, MP |

| 21. | Indo Autotech Ltd. | Faridabad |

| 22. | Machino Autocomp (P) Ltd. | Gurgaon |

| 23. | Neel Metal Products Ltd. | New Delhi |

| 24. | Krishna Maruti Ltd. | Gurgaon |

| 25. | Jay Bharat Maruti Ltd. | Gurgaon |

| 26. | NTF (India) Pvt. Ltd. | Gurgaon |

| 27. | Senior India (P) Ltd. | Gurgaon |

| 28. | Goshi India Auto Parts Pvt. Ltd. | Bawal |

| 29. | Bestex MM India Pvt. Ltd. | Rajasthan |

| 30. | Hirotech India Pvy. Ltd. | Pune |

| 31. | Fox Solutions | Silvassa |

| 32. | Green Fuel Energy Solutions Pvt. Ltd. | Gurgaon |

| 33. | Neometrix Engineering Pvt. Ltd. | Noida |

| 34. | SDL Auto Pvt. Ltd. | Faridabad |

| 35. | Emkay Auto Pvt. Ltd. | Indore |

| 36. | Majestic Auto Components | Gurgaon |

| 37. | Nagata India Pvt. Ltd. | Gurgaon |

| 38. | Many Others. |

Why Us

Customer satisfaction and timely delivery have been our forte that has helped us achieve new heights. We have been able to stand ahead of our competitors in this industry because we believe in delivering what we promise. See why you should choose us:

- State-of-the-art infrastructure

- Efficient Workforce

- Customized solution

- Ethical business policy

- Quality compliance with international standards

- Timely Delivery

- Complete integrated solution under one roof

- High customer satisfaction